In commercial construction and maintenance settings, protective paints protect surfaces exposed to harsh environments, chemicals, weathering, and regular wear and tear. Moreover, protective paints and coatings are integral to maintaining the longevity, safety, and functionality of surfaces and structures in diverse commercial and industrial applications. The correct application of paints and protective coatings ensures their durability, maximizing effectiveness and minimizing maintenance costs over time.

Painting brackets in construction may seem minor or not a priority at first glance, depending on factors such as budget, timeline, client preferences, and the overall design aesthetic of the project. However, brackets play a crucial role in construction by providing structural support, alignment, stability, versatility, flexibility in design, and ease of installation. Their importance cannot be overstated in ensuring the commercial buildings’ durability, safety, and functionality in built environments. These are why painting brackets should be a significant part of any commercial or industrial painting project.

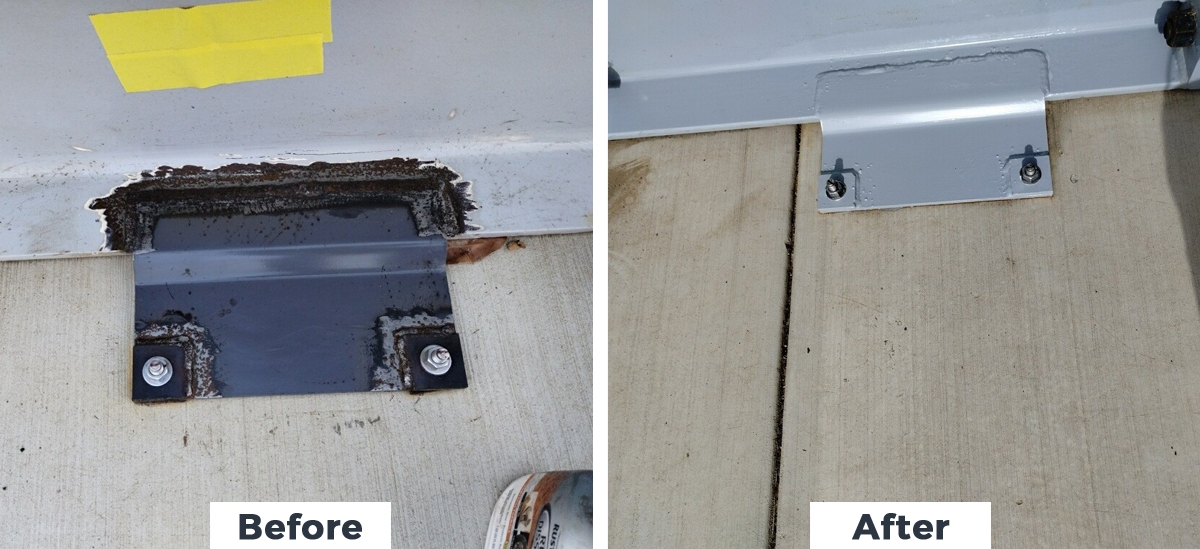

Recent bracket painting project done by Custom Painting, Inc.

Custom Painting, Inc. recently finished a bracket painting project in Milpitas, CA. In this project, we painted a total of 76 horizontal brackets. We are used to this type of project as we do similar work a few times a year.

The painting process

Our team first primed the brackets using Sherwin Williams Macropoxy 646, a high-solid, high-build, and fast-drying polyamide epoxy designed to protect steel in industrial environments.

For the finishing coat, our painters used the Sherwin Williams Pro Industrial DTM Acrylic, a water-based and corrosion-resistant acrylic coating formulated for interior and exterior applications, to match the adjacent material rails to which the brackets were welded.

The project took two days to complete; the first day was for prepping and priming, and the second was for applying the finishing coat.

Challenges faced

Throughout the project, the crew encountered weather problems due to frequent rain this time of the year. For this reason, the team had a 4-day window (one day prior, two days for application, and one day following) to complete the work properly. Luckily, the weather cooperated, the team had excellent primer and finish paint adhesion, and the custom color match turned out perfectly.

The role of brackets in commercial construction

What are brackets, and what types are used in commercial construction?

Brackets are structural elements that support beams, joists, or other components. Brackets come in varying shapes, sizes, and materials and serve different purposes depending on the specific application. Here are some common types of brackets used in construction:

- L-shaped brackets are the most common type of brackets. They feature a right-angle shape resembling the letter “L.” L-shaped brackets are often used for supporting shelves, countertops, beams, or other horizontal members.

- Corner brackets reinforce the corners of structures, such as framing in buildings or furniture. They are typically L-shaped and provide additional strength and stability to the joint.

- Angle brackets are similar to L-shaped brackets but are often longer and more versatile. They can support beams, trusses, or other structural elements at various angles.

- Custom brackets are tailored for specific structural needs or architectural aesthetics.

Examples of bracket application in structures

Brackets are crucial in structures, especially in construction and architectural design. Here are some examples of how brackets are applied in structural contexts:

- Supporting overhangs – Brackets evenly distribute the weight of construction overhangs to the main structure, ensuring stability.

- Beam and joist reinforcement – In wooden frame construction, brackets reinforce connections between beams and joists, providing additional support and resistance against shear and bending forces.

- Architectural aesthetics – Decorative brackets provide architectural detail and interest to buildings, often reflecting the style or period of the construction.

- Seismic retrofitting – In earthquake-prone areas, brackets are used in seismic retrofitting to strengthen existing buildings. They help secure the structure to the foundation and reinforce connections between different structural elements to improve earthquake resilience.

- Connecting trusses and girders – In larger structures, brackets connect trusses to girders or columns. These connections are vital for the structure’s stability, distributing loads evenly across the framework.

- Door and window installation – Specialized brackets are used to install windows and doors to ensure they are securely attached to the building’s framework, providing a reliable anchor point that can withstand operational stresses and environmental factors.

The importance of brackets in ensuring structural integrity

Brackets are critical in ensuring a building’s structural integrity in several ways:

- Load distribution – Brackets help distribute loads evenly across the structure. By connecting different structural elements, brackets ensure that weight and forces are spread out, reducing the risk of localized stress points that could lead to failure.

- Reinforcement – Brackets reinforce joints and connections between different parts of a structure, such as beams, columns, and walls. This reinforcement is vital in areas of high stress or dynamic forces, like wind or seismic activity.

- Stability and support – Brackets provide stability and support to various building components, ensuring that elements like balconies, staircases, and cantilevers are securely attached and supported.

- Flexibility – In earthquake-prone areas, brackets can provide the flexibility required for buildings, allowing them to move without causing significant damage. This flexibility is crucial for the longevity and safety of structures in seismically active regions.

- Aesthetic integration – Other than their structural benefits, brackets can also be designed to complement the architectural aesthetics of a building, providing functional support while enhancing visual appeal.

The purpose of painting brackets

Painting or providing protective coatings to construction brackets serves several important purposes, both practical and aesthetic:

Corrosion resistance

One of the primary reasons for applying protective coatings or paint to construction brackets is to prevent or slow down corrosion. Many construction brackets are made of metal that can oxidize and corrode over time when exposed to moisture, oxygen, and other environmental factors. Protective coatings form a barrier that minimizes the metal’s exposure to these elements, thereby extending the lifespan of the brackets.

Durability

A protective coating can significantly enhance the durability of construction brackets. By protecting against rust, corrosion, and wear, coatings ensure that the brackets maintain structural integrity over time. It is especially crucial in environments prone to harsh weather conditions or where the brackets are exposed to chemicals that could degrade the metal.

Aesthetic appeal

While practicality is often a concern, the aesthetic appeal of construction brackets cannot be overlooked, especially in visible areas. Coatings and paint can be used to improve the appearance of brackets, making them blend in or complement the surrounding structures. It is particularly relevant in architectural and public infrastructure projects where visual consistency and appeal are top priorities.

Chemical protection

Construction brackets may be exposed to various chemicals, depending on their location and application. Protective coatings can provide a layer of chemical resistance, protecting the metal from potentially harmful interactions with acids, alkalis, solvents, and other industrial chemicals.

UV protection

UV protection is another consideration for brackets used in outdoor applications. Continuous exposure to ultraviolet light from the sun can weaken and degrade materials over time. Certain coatings include UV inhibitors to protect against this form of degradation, extending the lifespan of the brackets.

Safety and identification

Coatings can also be used for safety purposes, such as color-coding brackets to signify different functions or load capacities, which can assist in safely and correctly using these components on construction sites.

Cost-effectiveness

In the long run, applying protective coatings or paint to construction brackets is cost-effective. It reduces the need for frequent replacements or repairs due to corrosion or wear, saving money and reducing maintenance efforts over the lifetime of a structure.

Applying protective coatings or paint on construction brackets is critical in ensuring their longevity, functionality, and aesthetic integration into construction projects.

What are the benefits of painting brackets?

Painting brackets, like any surface treatment or finish, offers several benefits that improve the appearance and longevity of the brackets. Here’s a rundown of the main advantages:

- Corrosion resistance – One of the primary benefits of painting metal brackets is the added protection against rust and corrosion. Paint acts as a barrier that prevents moisture and oxygen from coming into contact with the metal, reducing the risk of rust formation.

- Aesthetic appeal – Painting brackets can significantly enhance their appearance, allowing them to blend in with or complement the surrounding decor. This factor is particularly important in visible areas where the brackets support shelves or other features in homes and businesses.

- Color coordination – With a wide range of paint colors available, it’s possible to match the brackets to the color scheme of the room or the items they are supporting. This factor can create a cohesive and visually appealing look.

- Increased durability – A good quality paint can add a layer of protection against wear and tear. It is especially beneficial in environments where the brackets may be subject to physical impact or abrasion.

- Improved UV resistance – For brackets exposed to sunlight, certain types of paint can offer protection against UV radiation, which can otherwise lead to weakening of the material or fading of its color over time.

- Easy maintenance – Painted surfaces are generally easier to clean and maintain. Dust, dirt, and grime can be wiped off without specialized cleaning.

- Identification and marking – Painting brackets in different colors can serve as a method of identification, which can be useful in organizational systems or industrial settings where different bracket types serve various purposes.

- Increased resale value – In some cases, especially with antique or decorative brackets, a well-executed paint job can enhance their aesthetic appeal and, consequently, their resale value.

When deciding to paint brackets, choose the right type of paint for the material of the bracket (metal, wood, plastic, etc.) and the environment in which it will be used (outdoor, indoor, humid conditions, etc.). Proper surface preparation and application techniques are crucial in achieving a durable and attractive finish.

Challenges in painting brackets

Like many other commercial painting tasks, painting brackets can be challenging, especially if you aim for a professional or highly specific finish. Here are a few challenges that might come up:

- Material composition – Brackets can be made from various materials, including metal, wood, or plastic. Each material requires a different preparation process and type of paint. For instance, metal might need a rust-inhibiting primer, while plastic requires a primer that ensures paint adherence.

- Surface preparation – Proper surface preparation is key to achieving a smooth and durable finish. This might involve cleaning, sanding, and applying a primer. Any imperfections not addressed in this stage can significantly affect the final appearance.

- Complex shapes – Brackets often have intricate designs or hard-to-reach areas. This factor can make it difficult to apply paint evenly or to achieve a consistent finish in every nook and cranny without drips or missed spots.

- Drying and curing times – Different materials and types of paint have varying drying and curing times. Rushing through these stages or not allowing adequate time for each layer to dry can result in a tacky finish, fingerprints, or dust particles getting stuck in the paint.

- Finish and durability – Whether matte, satin, or glossy, achieving the desired finish requires specific types of paint and application techniques. Additionally, painted brackets often need to withstand handling and environmental conditions, requiring the paint to be durable and sometimes even resistant to chipping or corrosion.

- Safety and ventilation – Painting, especially spray painting, requires proper ventilation and safety gear to avoid inhaling fumes or getting paint on your skin.

- Consistency between multiple brackets – If you’re painting numerous brackets for use in the same space, achieving a consistent color and finish across all pieces can be challenging.

Addressing these challenges often requires patience, attention to detail, and sometimes trial and error to see what works best for the specific material and design of the brackets you’re working with.

What are the best practices in painting brackets?

Painting construction brackets can be a detailed task requiring a bit of know-how for the best results. Here are some tips and best practices to ensure a smooth and durable finish:

Step 1: Prepare the surface

- Clean the Brackets – Remove any dirt, grease, or rust from the brackets using a wire brush or sandpaper. Wiping new brackets with a degreaser or mineral spirits can remove protective oils or residues.

- Remove rust – If there’s rust, use a rust converter or a rust-removing solution to treat the area before painting. It will help prevent further corrosion under the paint.

- Sand the surface – Lightly sand the brackets with fine-grit sandpaper to create a surface the paint can adhere to more easily. It is especially important for smooth metal surfaces.

Step 2: Prime the surface

- Use a rust-inhibitive primer – Apply a primer designed for metal surfaces, preferably one that’s rust-inhibitive, to protect against corrosion. Spray primers offer an even coat, but be sure to do this in a well-ventilated area.

- Let it dry completely – Before painting, ensure the primer has dried completely according to the manufacturer’s instructions.

Step 3: Paint (or apply protective coating or finish)

- Choose the right paint, coating, or other finish – Use a paint, protective coating, or other finish suitable for metal surfaces. Oil-based paints are good for durability and rust resistance, but specialized metal paints are also available.

- Apply thin coats – It’s better to apply several thin coats than one thick coat. Thin coats dry faster, adhere better, and are less likely to drip or sag.

- Use spray paint, coating, or finish – For an even application without brush marks, spray paint can be an excellent choice. Again, ensure you’re in a well-ventilated area and use protective gear to avoid inhaling fumes.

- Allow proper drying time – Follow the manufacturer’s recommended drying time between coats before handling or installing the brackets.

Step 4: Add the finishing touches

- Apply a sealant – For extra protection, especially if the brackets are exposed to harsh weather conditions, consider applying a clear sealant over the paint. This can help extend the life of your paint job.

- Regular maintenance – Check the brackets periodically for signs of wear or rust, especially if installed outdoors. Touch up the paint as needed to maintain protection.

Safety and cleanup tips

Before painting:

- Use protective bear – When sanding, painting, or using chemicals, wear appropriate protective gear such as gloves, safety glasses, and a mask.

- Have proper ventilation – Work in a well-ventilated area to avoid inhaling dust, fumes, or vapors.

After painting:

- Clean up – Clean your brushes, spray nozzles, and any spills immediately after use to prevent the materials from hardening and to maintain a safe work environment.

- Do the proper disposal – Dispose of debris correctly and responsibly. It is best to ensure the paints are hardened and solidified before disposal instead of washing them down the drain. For hazardous waste, take it to your local hazardous waste collection agency.

Recommended paints and protective coatings

For metal brackets in construction, choosing paints and protective coatings is critical to ensure durability, resistance to corrosion, and adherence to safety and environmental regulations. Here are some highly recommended options:

- Epoxy coatings – Known for their durability and chemical resistance, they protect metal surfaces against corrosion. They are especially effective in harsh environmental conditions and are widely used in industrial settings.

- Polyurethane coatings – These are renowned for resisting UV radiation, making them an excellent choice for outdoor metal structures. Polyurethane coatings also provide a high-quality finish with outstanding gloss and color retention.

- Zinc-rich primers – Also known as galvanizing primers, they are used for superior protection against rust. Zinc acts as a sacrificial anode, protecting the metal even if the coating is scratched.

- Acrylic coatings – Acrylics are known for quick drying times and excellent color retention. They offer a durable finish that resists UV light, making them suitable for exterior applications.

- Alkyd coatings – These coatings are oil-based and offer good protection against moisture. Alkyd paints are often used for their smooth finish and resistance to wear, making them suitable for indoor and outdoor applications.

- Silicone coatings – Silicone-based coatings are high-temperature resistant and often used in environments requiring heat resistance. They also provide good water repellency.

- Powder coatings – Powder coatings are applied as a free-flowing, dry powder. They are known for their thick, uniform coatings that do not run or sag. Powder coatings provide a durable, corrosion-resistant finish and are environmentally friendly since they emit zero or near zero volatile organic compounds (VOCs).

- Ceramic coatings – This coating offers exceptional protection against corrosion and wear due to their high hardness and chemical stability. They are also effective in providing thermal insulation.

Paint or protective coating selection tips

When selecting a paint or protective coating for metal brackets in construction, consider the specific environmental conditions to which the metal will be exposed, such as moisture, chemicals, UV exposure, and physical wear. Additionally, adherence to local regulations and standards for environmental protection and safety should be considered. It’s also beneficial to consult a professional or manufacturer for product recommendations tailored to your project needs.

Maintenance and inspection schedule tips

Painting, maintaining, and inspecting metal brackets in commercial buildings ensures their longevity and structural integrity. Here are some tips for establishing regular maintenance and inspection schedules:

- Create a maintenance plan – Develop a comprehensive plan outlining specific tasks, schedules, and responsible parties for inspecting and maintaining the painted metal brackets.

- Follow manufacturer recommendations – Adhere to any maintenance guidelines provided by the manufacturer of the metal brackets. These guidelines may include recommended cleaning products, inspection intervals, and maintenance procedures.

- Schedule regular inspections – Inspect the painted metal brackets to identify wear, corrosion, or damage signs. Inspections should be performed at least annually, but more frequent inspections may be necessary depending on the building’s environment and usage.

- Check for paint damage – Look for any signs of paint damage, such as chipping, peeling, or flaking. Address any areas of damage promptly to prevent corrosion and deterioration of the metal.

- Inspect for corrosion – Examine the metal brackets for any signs of corrosion, rust, or oxidation. Corrosion can weaken the brackets and compromise their structural integrity. Treat corrosion promptly by removing rust and applying a suitable rust-inhibiting primer and paint.

- Clean regularly – Clean the painted metal brackets regularly to remove dirt, debris, and other contaminants contributing to paint degradation and corrosion. Use a mild detergent and water solution for cleaning, avoiding harsh chemicals that may damage the paint.

- Monitor load-bearing capacity – Regularly assess the load-bearing capacity of the metal brackets to ensure they can safely support their intended loads. Inspect for bending, distortion, or stress that may indicate overloading or structural issues.

- Inspect attachment points – Check the attachment points of the metal brackets to ensure they are securely fastened to the building structure. Tighten any loose bolts or screws and replace any damaged hardware as needed.

- Consider environmental factors – Consider environmental factors such as humidity, temperature fluctuations, exposure to corrosive substances, and proximity to saltwater when establishing maintenance schedules and inspection intervals.

- Keep records – Maintain detailed records of maintenance activities, inspections, and any repairs or modifications made to the painted metal brackets. This documentation can help track the condition of the brackets over time and identify any recurring issues.

By following these tips and implementing a proactive maintenance and inspection plan, you can help ensure the continued functionality and durability of painted metal brackets in commercial buildings.

Conclusion

In construction and maintenance, brackets are crucial in providing structural support, facilitating connections, ensuring alignment, and enhancing durability, safety, and aesthetics. There’s so much more to brackets than what meets the eye, so painting them should be an essential part and priority in your commercial property maintenance.

Correctly selecting paints or protective coatings, proper application techniques, and after-painting regular maintenance and inspection are recommended to ensure the brackets’ durability, functionality, useful life, and pleasing appearance in the long run.

Because of their scope and design complexity, commercial buildings generally require specialized coatings and finishes as protection against wear and tear, moisture, chemicals, and other environmental factors. Moreover, painting commercial buildings requires different application techniques, and only professional painters have the expertise and the tools to deliver the desired results.

For instance, brackets have painting or coating requirements that may differ from those of the other elements in a commercial building. Contact Custom Painting, Inc. now to prioritize bracket painting in your next project and discover the long-term advantages of investing in quality and care. Call us at 925-294-8062 or fill out our contact form to message us. We look forward to working with you and elevating your construction projects to new heights.